The Current State of Component Autoplacement

Component autoplacement has been a feature in electronic design automation (EDA) tools for decades. Major platforms like Altium Designer, Cadence Allegro, KiCad, and others offer various automated placement algorithms designed to help engineers position components on PCB layouts.

While these features represent significant engineering efforts and can provide value in specific scenarios, many PCB designers have found that autoplacement algorithms often require substantial manual intervention to achieve production-ready results. Understanding why this occurs can help us appreciate both the complexity of the placement problem and the opportunities for improvement.

How Current Autoplacement Algorithms Work

Algorithmic Approaches

Most autoplacement tools operate on optimization principles, typically focusing on minimizing connection lengths between components. This approach is mathematically sound and computationally tractable, making it a logical starting point for automation.

Altium Designer

Cluster Placer: Groups components based on connectivity and places clusters geometrically. Recommended for designs with fewer than 100 components.

Statistical Placer: Uses randomized algorithms with iterative improvement techniques. Better suited for larger designs but can be computationally intensive.

Cadence Allegro

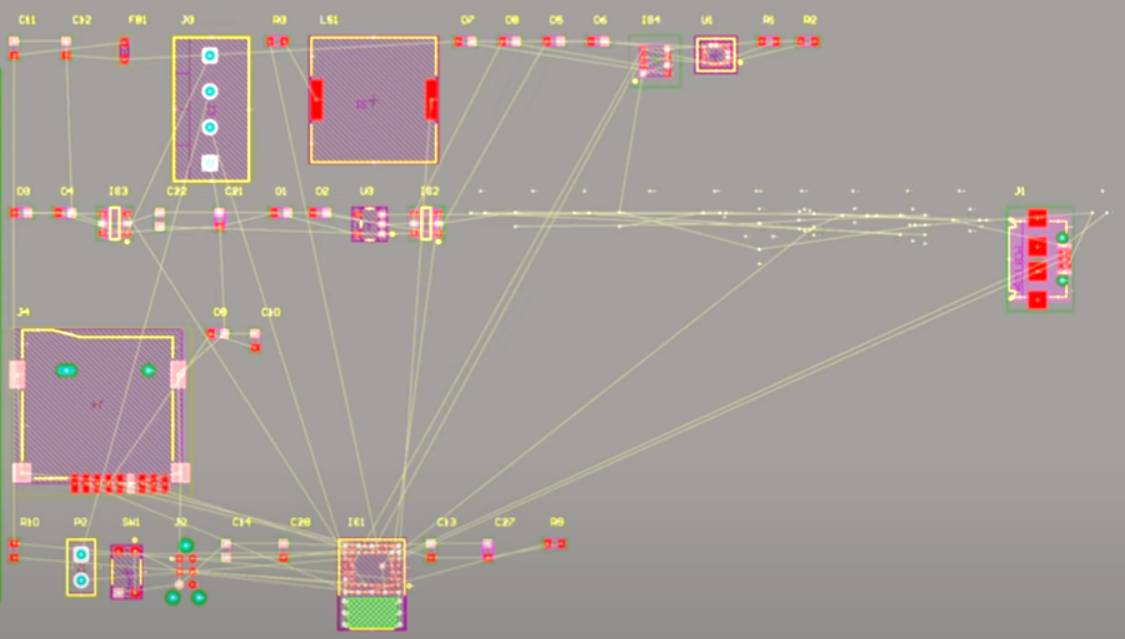

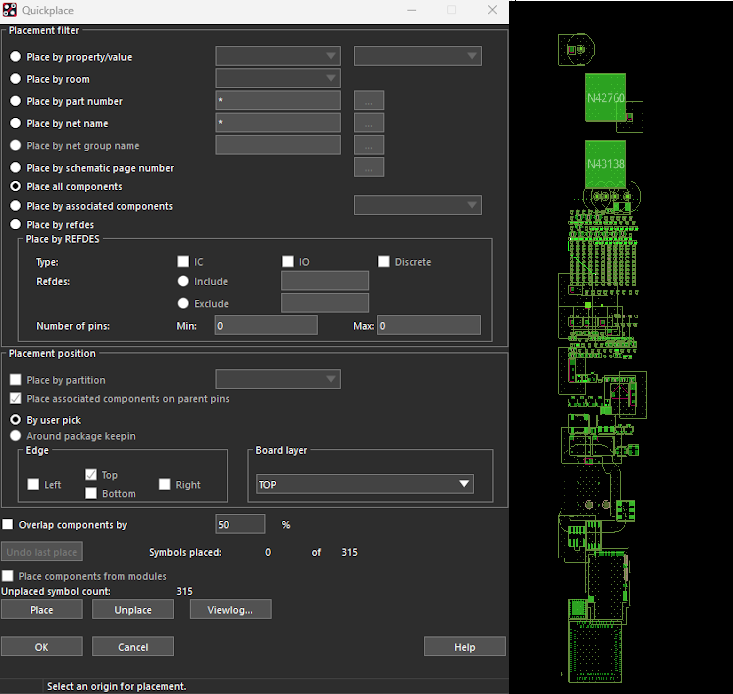

Quickplace: Provides initial component organization by distributing parts around board edges based on schematic hierarchy or functional groups.

Autoplace: Offers more comprehensive placement optimization with various configuration options.

Technical Challenges in Autoplacement

1. Multi-Objective Optimization Complexity

PCB design involves optimizing across multiple, sometimes conflicting objectives: electrical performance, mechanical constraints, thermal management, manufacturing requirements, and signal integrity. Traditional algorithms typically optimize for a single metric, such as total wire length, which may not capture all design requirements.

2. Domain-Specific Knowledge Requirements

Effective component placement requires understanding the functional relationships between components beyond simple connectivity. For example, decoupling capacitors should be placed close to their associated ICs, and sensitive analog circuits should be isolated from switching circuits.

3. Constraint Definition and Setup

Most autoplacement tools require extensive constraint setup to produce usable results. This includes defining keepout areas, component rooms, placement rules, and mechanical boundaries. The time required for proper constraint definition can sometimes approach the time needed for manual placement.

4. Computational Scalability

As design complexity increases, the solution space grows exponentially. Finding optimal placements for boards with hundreds of components can become computationally prohibitive, leading to algorithms that may terminate at local optima rather than global solutions.

Industry Experiences and Observations

User feedback and forum discussions across the PCB design community reveal common experiences with autoplacement tools:

| Tool | Feature | Common User Experience |

|---|---|---|

| Mentor PADS | Cluster Placement | Available but often requires significant manual refinement |

| KiCad | Auto Place Footprints | Provides basic organization but limited optimization |

| Proteus | Auto-placer | Functional for simple designs |

| Eagle | N/A | Focused on assisted manual placement tools |

These experiences suggest that while autoplacement can provide value as a starting point, most professional PCB designs benefit from manual refinement or hybrid approaches that combine automated assistance with engineering judgment.

Emerging Approaches and Innovations

The industry continues to evolve with new approaches to autoplacement. Recent developments include AI-enhanced algorithms and more sophisticated constraint handling systems.

AI-Enhanced Placement

Tools like Cadence's Allegro X AI represent efforts to incorporate machine learning and artificial intelligence into placement algorithms. These systems aim to learn from successful design patterns and apply that knowledge to new layouts.

Our Proprietary Algorithm

While traditional autoplacement focuses primarily on component positioning, our proprietary algorithms take a more holistic approach that considers the entire design flow from schematic analysis through final routing. We have developed these algorithms specifically to address the limitations of traditional autoplacement approaches, incorporating domain-specific knowledge and design intent understanding to generate more effective component placements.

Our PCB design automation technology addresses these challenges through:

- •Automatic analysis of design intent from schematic connectivity

- •Intelligent placement of edge components based on functional requirements

- •Grouping of critical components within defined form factors

- •Integration of placement and routing for optimal overall design

- •Automated routing through our intelligent engine that demonstrates how critical signals are routed and power/ground planes are created

- •Consideration of manufacturing and assembly requirements throughout the process

This approach aims to address the traditional limitations of autoplacement by incorporating domain knowledge and design intent understanding into the automation process, considering the complete design context rather than optimizing for isolated metrics.

Experience Advanced PCB Design Automation

See how modern automation technology can dramatically reduce your PCB design time while streamlining your design process and maintaining the quality and reliability your projects demand.

Request a Technical Demonstration