Quick Navigation

- 1. Component Placement Dependencies

- 2. Configuration Overhead

- 3. Power Distribution Network Limitations

- 4. Signal Integrity and Design Intent

- 5. Spaghetti Routing and Lack of Foresight

- 6. Via Usage and Layer Management

- 7. Post-Routing Refinement Requirements

- 8. The 99% Complete Problem

- 9. Manufacturing and Assembly Considerations

- 10. Design Methodology Integration

- 11. What Professionals Actually Do

- 12. How Our Automation Addresses These Challenges

- 13. Frequently Asked Questions

Introduction

PCB design automation has evolved significantly over the years, with autorouting technology representing one of the most ambitious attempts to streamline the design process. While the concept of automated trace routing offers compelling potential benefits—such as reducing design time and improving consistency—the practical implementation presents unique challenges that affect adoption in professional design environments.

Whether you're searching for "autorouting pcb" solutions, evaluating "pcb autoroute" tools, or researching pcb autorouting technology, understanding why traditional automation struggles helps designers make informed decisions about when automation adds value and when manual expertise remains essential.

This comprehensive analysis examines the specific technical and workflow considerations that influence how PCB designers approach routing decisions. By understanding these factors, we can better evaluate when automation provides value and when manual expertise remains the preferred approach for achieving optimal design outcomes.

For readers interested in a deeper dive into practical automation workflows, you can reference our detailed guides on Altium AI PCB routing and KiCad AI PCB routing, where we explore real-world implementation strategies and design trade-offs.

1. Component Placement Dependencies: The Foundation Challenge

The most fundamental limitation of current autorouting technology lies in its separation from component placement optimization. Effective PCB design requires a holistic approach where component placement and routing decisions are made in coordination, as each directly impacts the success of the other.

The Placement-Routing Interdependency

- Fixed Placement Constraints: Traditional pcb autoroute algorithms operate on pre-placed components, missing opportunities to optimize placement for better routing outcomes

- Routing Efficiency Limitations: Suboptimal component placement can create routing bottlenecks that no algorithm can effectively resolve

- Missed Optimization Opportunities: Small component position adjustments could dramatically improve routing quality, but autorouters cannot make these decisions

Real-World Impact

Professional designers often find that moving a component by just a few millimeters can resolve complex routing challenges or improve signal integrity. Current autorouting technology cannot recognize these opportunities, leading to suboptimal results even when the routing algorithm performs well within its constraints.

2. Configuration Overhead: Time Investment vs. Results

One of the most frequently cited frustrations with autorouting technology is the extensive setup time required to achieve acceptable results. The configuration process often becomes so complex and time-consuming that it negates the primary benefit of automation—saving design time.

Configuration Complexity

- Design Rule Setup: Comprehensive constraint definition for traces, vias, layer usage, and spacing requirements

- Priority and Weighting Systems: Complex algorithms require detailed guidance on routing priorities and trade-off decisions

- Net Class Management: Different signal types require distinct routing strategies and constraint sets

- Layer Stack Coordination: Proper impedance control and signal integrity require detailed layer and material specifications

The Learning Curve Challenge

Even experienced PCB designers report that mastering autorouting configurations requires significant time investment. The complexity of achieving professional-quality results through automation often requires extensive learning and experimentation with tool settings and constraint definitions.

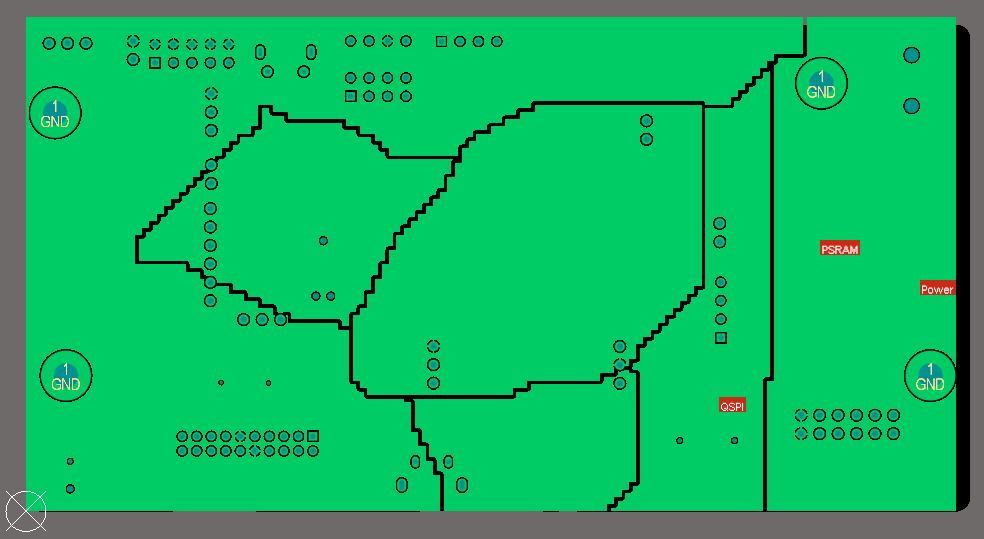

3. Power Distribution Network Limitations

A critical gap in most autorouting solutions is the lack of integrated power distribution network (PDN) design capabilities. Power plane generation, via stitching, and power integrity optimization remain manual tasks that must be completed separately from the autorouting process.

Power Design Requirements

- Power Plane Generation: Automatic creation and management of power and ground planes across multiple layers

- Via Stitching Strategy: Strategic placement of stitching vias for optimal power distribution and EMI control

- Decoupling Integration: Coordinated placement of decoupling capacitors with power distribution design

- Current Density Analysis: Verification that power traces and planes can handle required current loads

The Workflow Gap

The separation between signal routing and power distribution design creates workflow inefficiencies and potential integration issues. Designers must complete power network design manually, then configure autorouting to work around these constraints, often resulting in suboptimal overall solutions.

4. Signal Integrity Considerations in High-Speed Designs

Modern electronic systems increasingly require careful attention to signal integrity, particularly for high-speed digital signals, differential pairs, and controlled impedance applications. Traditional autorouting algorithms often struggle with these requirements, producing layouts that may be functionally connected but electrically inadequate.

High-Speed Design Challenges

- Differential Pair Routing: Maintaining consistent spacing and coupling throughout the signal path

- Length Matching: Precise control of trace lengths for timing-critical signal groups

- Controlled Impedance: Coordination of trace geometry with layer stackup for target impedance values

- Crosstalk Minimization: Strategic spacing and routing patterns to reduce signal interference

- Return Path Management: Ensuring continuous return paths for high-frequency signals

EMI and EMC Considerations

Electromagnetic interference and compatibility requirements add another layer of complexity to high-frequency design. Effective EMI control requires understanding of antenna theory, shielding strategies, and grounding techniques that extend beyond basic connectivity algorithms.

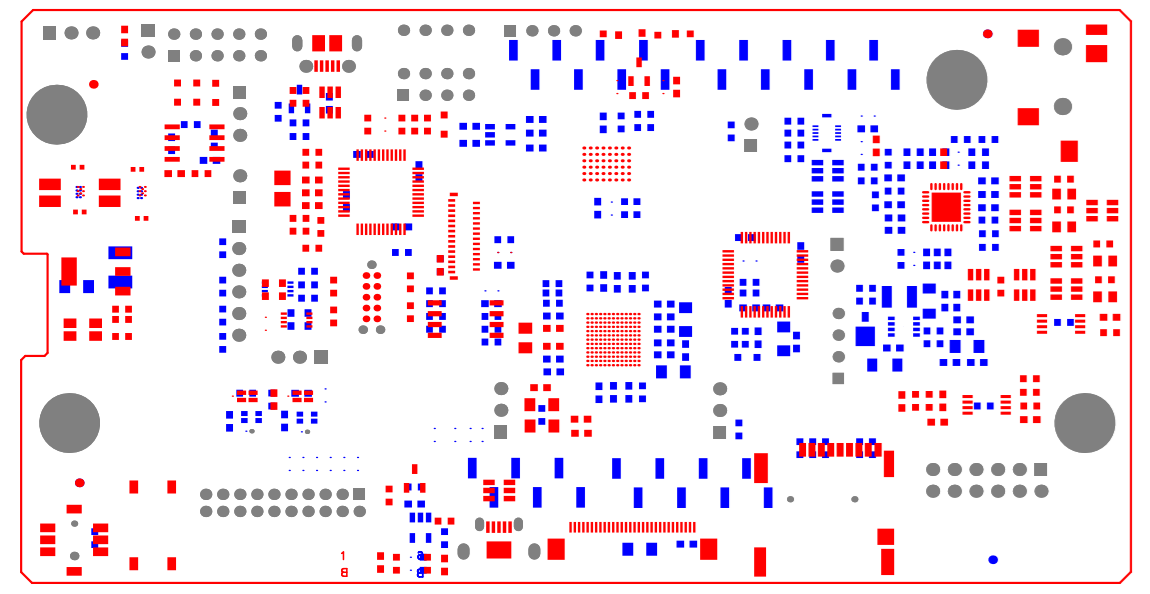

5. Route Optimization and Aesthetic Considerations

Professional autorouting pcb design extends beyond functional connectivity to include considerations of layout aesthetics, manufacturing efficiency, and design maintainability. Traditional autorouting algorithms often produce results that, while electrically correct, fail to meet the standards expected in commercial product development.

Quality and Aesthetics Issues

- Excessive Meandering: Unnecessary trace length and complex routing patterns that waste board space

- Poor Trace Optimization: Routes that ignore available space and create unnecessarily tight spacing

- Recognizable Automation: Layouts that are immediately identifiable as autorouted, suggesting amateur or rushed design work

- Inconsistent Patterns: Lack of design coherence and professional appearance standards

Professional Standards

In commercial PCB development, design appearance and organization directly impact perceived product quality and can affect design review processes, manufacturing feedback, and customer confidence. Professional designers develop routing patterns and aesthetic standards that reflect both technical competence and attention to detail.

6. Via Usage and Layer Management Strategies

Effective via usage and layer management are critical aspects of professional PCB design that significantly impact both electrical performance and manufacturing costs. Traditional autorouting algorithms often struggle with strategic via placement and layer transition optimization.

Via Optimization Challenges

- Excessive Via Count: Algorithms that prioritize connectivity over optimization often create more vias than necessary

- Poor Via Placement: Strategic considerations for signal integrity, power distribution, and manufacturing are often overlooked

- Layer Bias Problems: Preferential use of certain layers leading to unbalanced routing distribution

- Manufacturing Cost Impact: Via count and complexity directly affect fabrication costs, especially for HDI designs

Layer Management Strategy

Professional PCB design requires careful consideration of layer usage for optimal signal integrity, power distribution, and manufacturing efficiency. This includes strategic assignment of signal layers, proper power plane management, and coordination with mechanical constraints.

7. Post-Routing Refinement Requirements

Even when autorouting produces functionally correct results, the output typically requires extensive manual refinement to meet professional standards. This post-processing requirement often eliminates the time savings that automation was intended to provide.

Common Refinement Needs

- Route Cleanup: Removing unnecessary meandering and optimizing trace paths

- Via Reduction: Eliminating redundant vias and optimizing layer transitions

- Spacing Optimization: Adjusting trace spacing for better utilization of available board area

- Design Rule Verification: Ensuring compliance with manufacturing and assembly requirements

- Documentation Updates: Updating design documentation to reflect final routing decisions

Workflow Integration Challenges

The need for extensive post-routing cleanup creates workflow complications, particularly in team-based design environments where different engineers may be responsible for placement, routing, and verification activities.

8. Incomplete Routing Resolution

One of the most frustrating aspects of autorouting technology is the frequent failure to achieve 100% routing completion. Designs that appear straightforward to experienced engineers often result in 80-90% completion rates, leaving critical connections unrouted.

Completion Rate Challenges

- Algorithm Limitations: Inability to find routing solutions that experienced designers can identify quickly

- Constraint Conflicts: Overly restrictive design rules preventing completion of otherwise feasible routes

- Optimization Dead Ends: Algorithms getting trapped in local optimization minima

- Complex Geometry Handling: Difficulty with irregular board shapes and complex mechanical constraints

Manual Intervention Requirements

When autorouting fails to complete all connections, the remaining nets often require not just manual routing, but sometimes complete re-routing of sections to accommodate the final connections. This can result in more work than starting with manual routing from the beginning.

9. Manufacturing and Assembly Considerations

Professional PCB design must account for a wide range of manufacturing and assembly constraints that extend beyond basic design rule compliance. Traditional autorouting algorithms often lack the comprehensive understanding of these requirements necessary for production-ready designs.

Design for Manufacturing (DFM) Integration

- Fabrication Constraints: Trace width, spacing, and via requirements specific to chosen manufacturing processes

- Assembly Considerations: Component accessibility, test point placement, and rework accessibility

- Thermal Management: Heat dissipation and thermal via placement strategies

- Cost Optimization: Layer count, via usage, and complexity factors that impact manufacturing costs

Real-World Manufacturing Requirements

Modern PCB manufacturing involves complex trade-offs between electrical performance, mechanical constraints, cost targets, and production schedules. Professional designers must consider factors such as panel utilization, test strategy, and supply chain compatibility that traditional autorouting algorithms cannot evaluate.

10. Design Methodology and Best Practice Integration

Every organization and experienced designer develops specific methodologies, design patterns, and best practices that reflect their experience, application requirements, and quality standards. Traditional autorouting tools cannot replicate these established approaches, often producing results that conflict with proven design strategies.

Methodology Integration Challenges

- Company-Specific Standards: Internal design guidelines and quality requirements that extend beyond basic design rules

- Application-Specific Patterns: Routing strategies optimized for specific types of circuits or operating environments

- Experience-Based Decisions: Design choices that reflect years of experience with similar applications and problems

- Quality Standards: Aesthetic and organizational standards that reflect professional design practices

The Human Expertise Factor

Professional PCB design involves significant engineering judgment, pattern recognition, and creative problem-solving that extends beyond algorithmic optimization. Experienced designers bring understanding of physics, manufacturing, and application requirements that cannot be easily encoded in routing algorithms.

11. What Professionals Actually Do

While autorouting continues to struggle with fundamental limitations, experienced PCB designers have developed sophisticated approaches that combine the best aspects of automation with human expertise and engineering judgment. Instead of relying solely on pcb autoroute functionality, professionals use targeted automation features alongside manual control.

Interactive Routing: The Sweet Spot

Smart designers use interactive routing as the sweet spot where software helps you route manually while providing real-time feedback about design rules and constraints. You maintain control while the computer handles mechanical constraints, design rule checking, and basic optimization tasks.

📋 The Strategic Approach

- Power and Ground First: Establish solid power distribution before routing signals

- Critical Signals Next: Route high-speed clocks and sensitive analog signals carefully

- Bulk Routing: Use semi-automated tools for less critical connections

- Cleanup and Optimization: Review everything for manufacturability

Modern Routing Aids That Actually Work

While full autorouting struggles, specific automated functions provide genuine value when used strategically:

- Length Matching: Automatically match trace lengths for timing-critical nets

- Differential Pair Routing: Maintain proper spacing and impedance during interactive routing

- Via Stitching: Automatically place vias to maintain ground plane integrity

- Real-time DRC: Catch violations as you route, preventing downstream problems

- Push and Shove: Automatically adjust existing routes when adding new traces

What You Should Do Instead

1. Master Interactive Routing

Learn your CAD tool's interactive features thoroughly. These provide the best balance of automation and control, letting you route efficiently while maintaining quality. Focus on keyboard shortcuts, routing modes, and real-time constraint checking.

2. Develop Smart Strategies

Don't route randomly. Create systematic approaches based on your application requirements:

- High-Speed Digital: Focus on signal integrity and length matching

- Power Electronics: Prioritize current handling and thermal management

- Mixed-Signal: Separate analog/digital with careful grounding strategies

- RF Designs: Consider impedance control and return paths

3. Use Automation Where It Makes Sense

Some automated functions actually work well and should be leveraged:

- BGA fanout routing for escape strategies

- Power plane generation and copper pouring

- Via stitching for ground integrity

- Design rule checking and verification

- Length tuning for matched signal groups

4. Invest in Your Skills

The most productive designers understand both tools and electrical principles. Continuously develop expertise in:

- Signal integrity fundamentals and high-speed design

- Power distribution design and thermal management

- Manufacturing constraints and DFM principles

- Advanced routing techniques and optimization strategies

💡 Professional Insight

The most successful PCB designers view automation as a tool to enhance their capabilities rather than replace their expertise. They use automated functions strategically while maintaining control over critical design decisions that impact electrical performance, manufacturability, and product success.

12. How Our PCB Design Automation Addresses These Core Challenges

While traditional autorouting technology struggles with the challenges outlined above, modern advances in PCB design automation offer solutions that address many of these fundamental limitations. Our intelligent automation platform directly tackles six of the ten major challenges through innovative approaches that integrate engineering expertise with automated optimization.

✅ Intelligent Component Placement

Integrated Placement-Routing Optimization: Unlike traditional autorouters that work with fixed component placement, our system optimizes component placement and routing simultaneously, ensuring that both decisions support each other for optimal results.

✅ Zero Configuration Overhead

Embedded Design Intelligence: Designs are ready in under an hour with built-in design rules and constraint verification, eliminating the extensive setup time typically required for autorouting configuration.

✅ Integrated Power Distribution

Comprehensive PDN Design: Automated power plane generation and management ensures that power distribution design is coordinated with signal routing for optimal electrical performance and EMI control.

✅ Built-in Signal Integrity

High-Speed Design Optimization: Controlled impedance calculations, differential pair routing, and length matching requirements are automatically incorporated into the design process.

✅ Optimized Via Management

Strategic Via Placement: Via count and placement are optimized for both electrical performance and manufacturing cost, with intelligent layer transition strategies that support signal integrity requirements.

✅ Manufacturing-Ready Output

Integrated DFM Compliance: Design for manufacturing and assembly requirements are built into the automation process, ensuring that generated designs meet production requirements without additional verification steps.

🚀 The Future of PCB Design Automation

Rather than simply automating traditional routing algorithms, our approach embeds engineering expertise and proven design practices directly into the automation engine. This results in designs that not only route successfully but meet the quality and performance standards required for professional applications.

13. Frequently Asked Questions

What's the biggest misconception about PCB autorouting?

That routing is the hard part. In practice, placement quality and design intent determine whether routing succeeds or fails.

Why do professional PCB designers still avoid full autorouting?

Traditional autorouters operate on fixed placement and limited design context. They lack real understanding of SI/PI intent, power distribution strategy, and manufacturability, which leads to excessive cleanup. In practice, the time spent configuring and fixing autorouted designs often exceeds the time saved.

What should teams focus on instead of chasing autorouting?

Improving placement discipline, constraint definition, power integrity planning, and review workflows yields far greater returns than relying on blind, post-placement autorouting.

Is "push-button PCB design" or "one-shot automation" a realistic goal?

Not for production boards. Professional PCB design involves trade-offs, judgment, and application-specific knowledge that must remain human-controlled, even when assisted by automation.

What's the difference between autorouting pcb tools and modern PCB design automation?

Traditional pcb autoroute tools focus only on trace routing after component placement is fixed. Modern automation platforms integrate placement optimization, power distribution, signal integrity, and routing into a coordinated workflow that addresses design holistically rather than treating routing as an isolated step.

Experience the Next Generation of PCB Design Automation

Ready to move beyond the limitations of traditional autorouting? Our intelligent automation platform addresses the fundamental challenges that have kept PCB designers relying on manual methods—delivering complete, professional-quality designs in under an hour instead of days.

What makes our approach different:

- Understands your schematic to extract design intent, functional blocks, and critical signal paths

- Zero configuration overhead with embedded engineering expertise – no hours of constraint setup

- Controlled automation where you maintain final decision control with verification at each stage

- Delivers complete designs (placement + power + routing + DFM) in coordinated, integrated workflow

- Manufacturing-ready output with professional quality and built-in compliance checks